Stripped screws can derail your project, making them difficult to remove and leaving your work unfinished. But don’t worry—with the right techniques and tools, you can avoid stripping screws, remove damaged ones, and replace them with reliable fasteners. Here’s everything you need to know to keep your projects moving forward smoothly with Big Timber Fasteners.

Common Causes of Stripped Screws

Many factors can lead to stripped screws, but most are entirely avoidable:

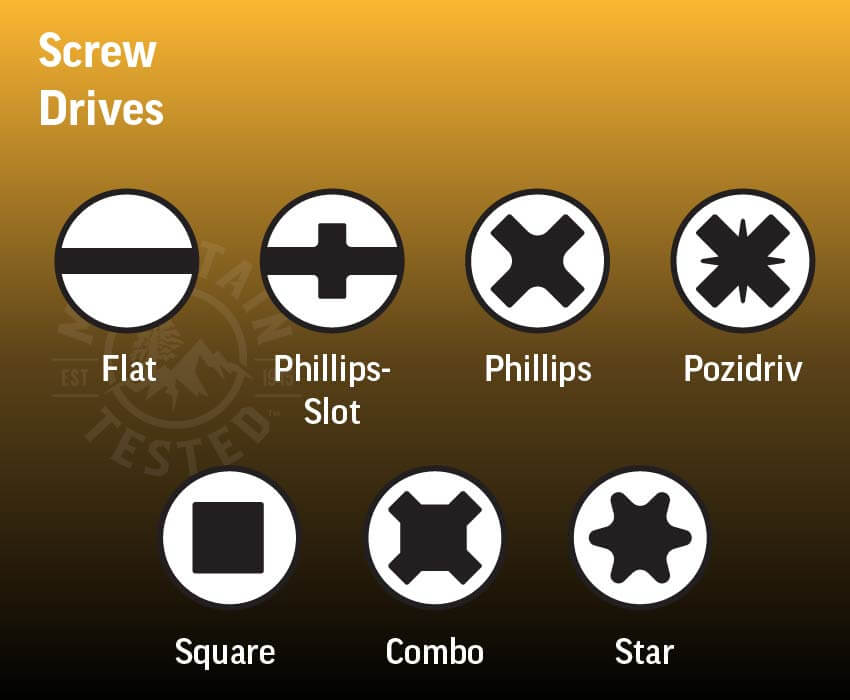

- Incorrect Screwdriver Size: Using a driver that’s too big or small can damage the screw head.

- Wrong Screwdriver Type: Not matching the tool to the screw head (e.g., Phillips vs. Star Drive).

- Low-Quality Fasteners: Cheap screws are more likely to strip under pressure.

- Excessive Torque or Misuse: Using too much force or driving screws at an improper angle increases the risk of stripping.

Avoid these issues by using high-quality fasteners like Big Timber screws and following proper installation techniques.

Avoiding Stripped Screws When Using a Power Drill

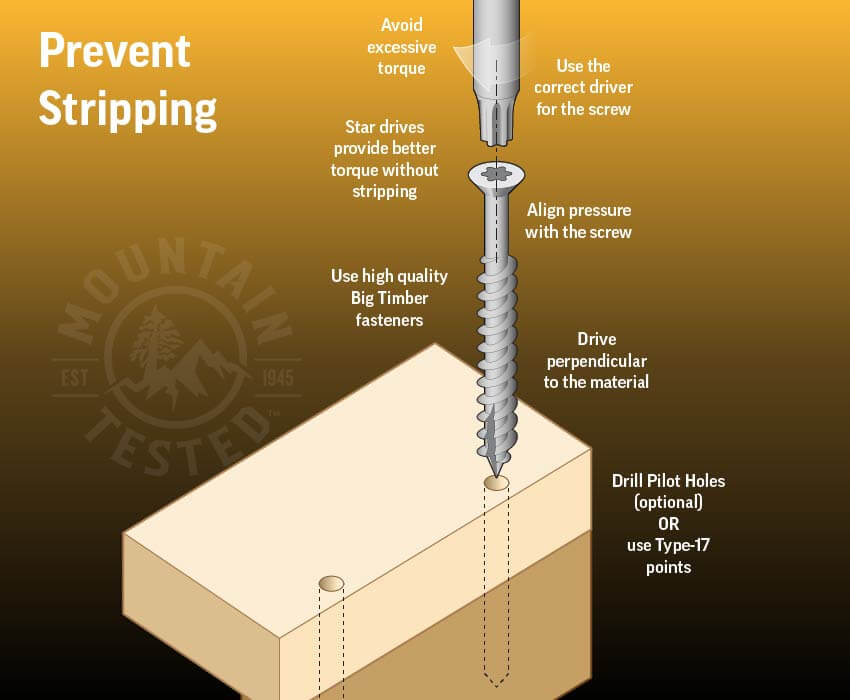

Power drills make quick work of installations, but improper use can lead to stripped screws. Follow these steps:

- Drill Pilot Holes (Optional)

- Pilot holes reduce resistance and make driving screws easier. Use a bit slightly smaller than the screw shank.

- With Big Timber screws, pilot holes are optional, thanks to their Type-17 cutting tips, which allow for smooth insertion without pre-drilling.

- Adjust Drill Force

- Start with the lowest clutch setting and gradually increase it until you find the right torque. This prevents over-tightening, which can strip the screw head.

- Align and Apply Pressure Correctly

- Keep the drill perpendicular to the surface. Apply steady pressure as resistance increases, ensuring the screw drives straight without slipping.

Avoiding Stripped Screws When Using a Screwdriver

Manual screwdrivers provide more control, reducing the likelihood of stripping screws. Use these tips for best results:

- Drill Pilot Holes (Optional)

- Pilot holes help the fastener sink into the material easily. If you’re using Big Timber screws, their Type-17 tips eliminate the need for pre-drilling.

- Place Screws Correctly

- Avoid driving screws too close to the edge of the material or unevenly spaced. Proper placement ensures stability and prevents damage to the structure.

- Choose a Strip-Resistant Drive

- Fasteners with a Star Drive provide more contact points, allowing for a stronger grip and reducing the chance of stripping.

How to Remove a Stripped Screw

If a screw becomes stripped, follow these methods to remove it:

Using Pliers

- Clamp a pair of locking pliers onto the screw head.

- Rotate the pliers counterclockwise slowly to avoid breaking the screw.

Using a Power Drill

- Drill into the screw head using a bit designed for metal.

- Once the bit is secure, set the drill to reverse and extract the screw carefully.

Using a Rubber Band for Grip

- Place a rubber band over the screw head.

- Position your screwdriver or drill over the band, applying firm pressure.

- Turn counterclockwise to remove the screw without further damage.

Replacing a Stripped Screw with a Big Timber Screw

Once you’ve successfully removed the stripped screw, it’s important to replace it with a high-quality fastener that won’t strip:

- Select the Right Big Timber Screw

- Choose a screw that matches your material and application. For most projects, screws with a Star Drive and Type-17 cutting tips ensure smooth and secure installation.

- Assess the Damage

- Inspect the hole for signs of wear. If necessary, drill a slightly larger pilot hole or fill and reinforce the area with wood filler before inserting the new screw.

- Drive the Replacement Screw

- Use a power drill or manual screwdriver to install the Big Timber screw. With its strip-resistant design and advanced cutting tip, you can trust it to hold securely without the risk of damage.

Replacing stripped screws with Big Timber Fasteners ensures your project remains durable, reliable, and professional.

Big Timber Fasteners: Your Solution to Stripped Screws

Big Timber screws are built for durability and precision, featuring Star Drives for a strong grip and Type-17 points for easy installation without pre-drilling. Whether you’re avoiding stripping, removing damaged screws, or replacing them, our fasteners provide the reliability you need to keep your projects on track.

Ask your local retailer today to stock up on Mountain Tested™ fasteners and experience the Big Timber difference.