Drilling pilot holes is a common step in many construction and woodworking projects. Pilot holes act as a guide for screws, ensuring precise placement, reducing material damage, and helping to create strong, stable connections. But what if there was a way to eliminate this extra step and save time without sacrificing quality?

This guide explores the importance of pilot holes, when they’re necessary, and how Big Timber screws with a Type 17 tip can make your projects faster and easier by eliminating the need for pre-drilling in many cases.

What Are Pilot Holes, and Why Are They Important?

Pilot holes are small, pre-drilled holes that prepare a material for a screw or fastener. They serve several purposes that improve the outcome of a project:

- Precision and Placement

Pilot holes act as a guide for screw placement, ensuring hardware is perfectly aligned. They help prevent the drill bit from slipping, which is essential for creating accurate and even connections.

- Security and Safety

A pilot hole allows the screw to seat securely within the material, reducing the likelihood of loosening over time. This enhances the stability and longevity of your project.

- Prevents Damage

- Avoids Splitting: Driving screws directly into wood can cause splitting, especially near the edges. Pilot holes minimize this risk by relieving stress on the material.

- Protects Tools: Without a pilot hole, drilling into hard materials can strain your drill bits, leading to premature wear or breakage.

- Efficient Drilling

Pilot holes remove excess material, making it easier to drive screws. This can speed up the drilling process, especially in dense or hardwood materials.

When Are Pilot Holes Recommended?

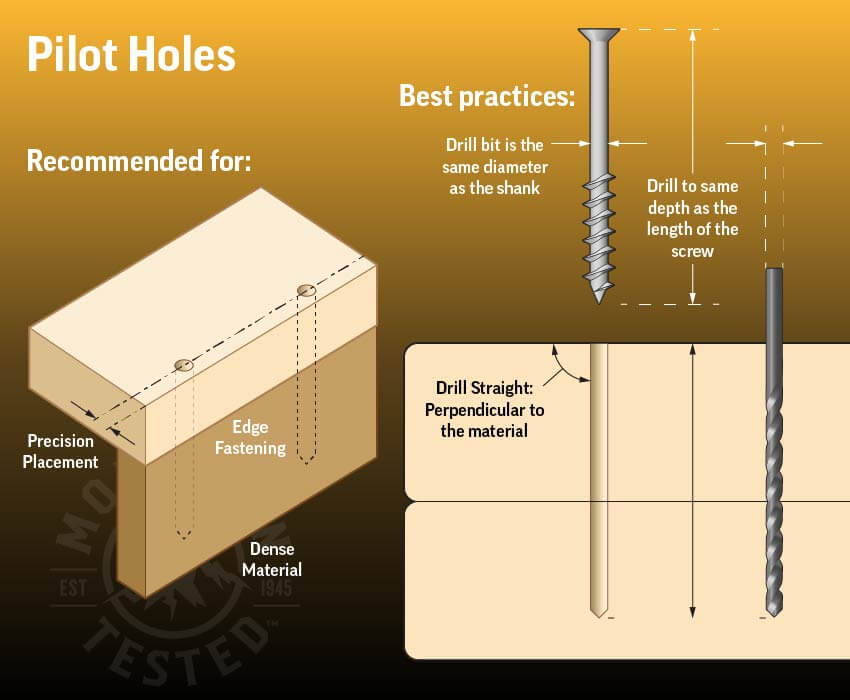

There are specific scenarios where pilot holes are highly recommended:

- Edge Fastening: Screwing into the edge of wood increases the risk of splitting. Pilot holes ensure the thread cuts directly into the material without causing cracks.

- Dense Materials: For hardwoods, metal, or composite materials, pilot holes reduce resistance and improve screw performance.

- Precision Projects: In projects requiring exact placement, pilot holes provide the accuracy needed to ensure structural stability and safety.

How to Drill a Pilot Hole

- Choose the Right Drill Bit: The diameter of the pilot hole should match the shank of the screw (the solid, non-threaded part).

- Match the Depth: Drill the pilot hole to the same depth as the screw being used. A bit stop or tape marker can help with accuracy.

- Drill Straight: Keep the drill perpendicular to the material to ensure a secure and even hole.

Eliminating the Need for Pilot Holes with Big Timber Screws

While pilot holes can improve screw performance, they aren’t always necessary—especially when using fasteners designed to eliminate this extra step. Big Timber screws with a Type 17 tip are engineered to drive into materials without requiring a pilot hole, saving you time and effort.

What Is a Type 17 Tip?

A Type 17 tip features a sharp point with a cut-out flute that acts like a drill bit. This design:

- Self-Drills: Removes material as the screw is driven in, mimicking the benefits of a pilot hole.

- Reduces Splitting: The flute relieves pressure on the material, preventing cracks or splits.

- Increases Efficiency: Cuts through wood, composite, and even some metal materials with ease.

Benefits of Big Timber Screws with Type 17 Tips

- Time Savings: Skip the pre-drilling step without compromising precision or strength.

- Reduced Material Damage: The Type 17 tip minimizes splitting and cracking, even near edges.

- Versatile Applications: From framing and decking to fencing and trim work, Big Timber screws perform across a wide range of projects.

Examples:

- BTX Screws: Ideal for wood-to-wood connections in framing, decking, and general construction.

- SWD Screws: Perfect for softwood decking projects.

- SCTX Screws: Made from 316 stainless steel, these screws excel in coastal or high-moisture environments.

When to Choose Type 17 Tip Screws Over Pilot Holes

While Big Timber screws eliminate the need for pilot holes in most cases, there are instances where pre-drilling is still recommended:

- Extremely Dense Materials: For ultra-hardwoods or thick metal, pilot holes may still enhance performance.

- Precision-Critical Projects: When exact placement is vital, such as in fine woodworking or intricate designs, a pilot hole can ensure perfection.

Build Smarter with Big Timber Screws

Pilot holes have long been a go-to solution for improving screw performance, but with Big Timber screws featuring Type 17 tips, you can achieve the same benefits without the extra step. Save time, reduce material damage, and simplify your projects with fasteners designed to perform under the toughest conditions.

Visit your local retailer or explore our Fastener Finder Tool at www.bigtimberfasteners.com to find the perfect screws for your next project.

This blog captures SEO by addressing common queries about pilot holes while pivoting to showcase the time-saving advantages of Big Timber’s Type 17 screws. Let me know if you’d like to refine it further!