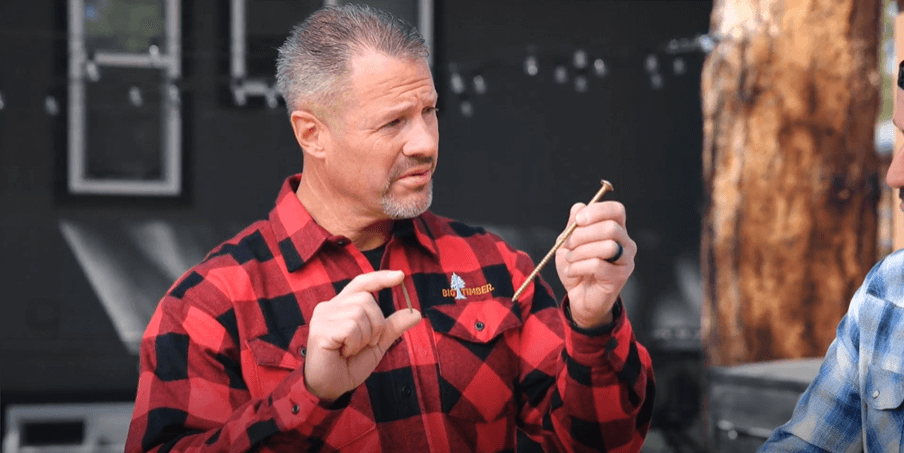

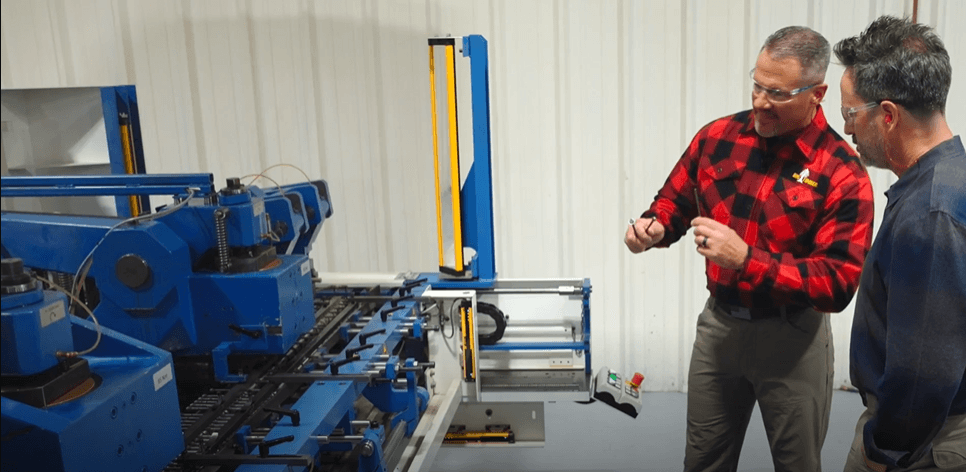

Factory Tour—How Screws are Made

Have you ever wondered how Big Timber construction grade fasteners are made? We’ve got the video for you! In Episode 8 of our Screw 101 series, we’re taking you where few ever get to go: inside the fastener manufacturing factory. This behind-the-scenes tour isn’t just about watching machines at work—it’s about showing the precision, more…

Read More