Every screw is a marvel of engineering, with each component carefully designed to contribute to its strength, function, and ease of use. Understanding the anatomy of a screw can help you select the right fastener for the job and maximize your project’s durability and efficiency.

At Big Timber Fasteners, we take pride in crafting screws that excel in every application, thanks to tried-and-true features like the Star Drive and the Type 17 tip. Here’s a closer look at the key parts of a screw and how they work together for superior performance.

-

The Head: Anchoring the Screw in Place

The head is the top of the screw, providing a surface for contact with the material and the tool. Its shape can vary depending on the application, offering different levels of flushness or grip. Some common head styles include:

- Flat Head: Sits flush with the surface, ideal for applications like decking and framing.

- Pan Head: Slightly rounded for a smooth appearance, often used in furniture assembly.

- Washer Head: Includes an integrated washer to increase pull-through strength, perfect for heavy-duty projects.

At Big Timber, we offer screws with a variety of head types to deliver stability, strength, and a clean finish for a range of applications.

-

The Drive: Getting the Screw Where It Needs to Go

The drive is the shape or recess in the head of the screw, determining the tool used to install or remove it. Each drive type offers unique advantages:

- Star Drive: The six-lobed design on most Big Timber screws provides exceptional torque, reduces cam-out, and minimizes slippage, making it ideal for high-stress applications.

- Robertson Drive (Square): Invented by P.L. Robertson, this design is known for its secure fit, preventing driver slippage. It’s commonly used in woodworking, drywall, and furniture assembly, especially in Canada.

- Phillips Drive: A plus-shaped design offering balanced torque control, best for general-purpose applications like household repairs and light-duty projects.

- Hex Drive: A hexagonal socket drive, ideal for heavy-duty tasks requiring high torque, such as construction and machinery assembly.

At Big Timber, we prioritize the Star Drive for its superior performance and reduced risk of cam-out.

-

The Shank: The Backbone of the Fastener

The shank is the smooth section of the screw between the head and the threads. It plays a crucial role in the fastener’s structural integrity:

- Load-Bearing Strength: Helps the screw resist applied forces, ensuring stability.

- Durability: Designed to prevent shearing under heavy loads.

Selecting the appropriate shank diameter and length is key to ensuring optimal performance in your application.

-

The Knurl: Easing the Installation Process

Located below the shank, the knurl serves as a built-in boring tool, simplifying installation:

- Torque Reduction: The knurl slightly enlarges the hole as the screw drives in, reducing resistance and making installation easier.

- Improved Friction Control: Helps achieve smoother driving and reduces wear on tools.

This feature is particularly beneficial when working with dense materials or using longer screws, ensuring precision and ease of use.

-

The Thread: Holding It All Together

Threads are the helical grooves that wrap around the lower portion of the screw. They ensure a strong connection by converting rotary motion into linear force:

- Strong Connections: Threads lock the screw securely into the material, resisting pullout forces.

- Ease of Removal: The thread design allows for smooth disassembly when needed.

Big Timber screws feature aggressive threads that provide maximum withdrawal strength and reliability in any application.

-

The Tip: Precision at the Point of Contact

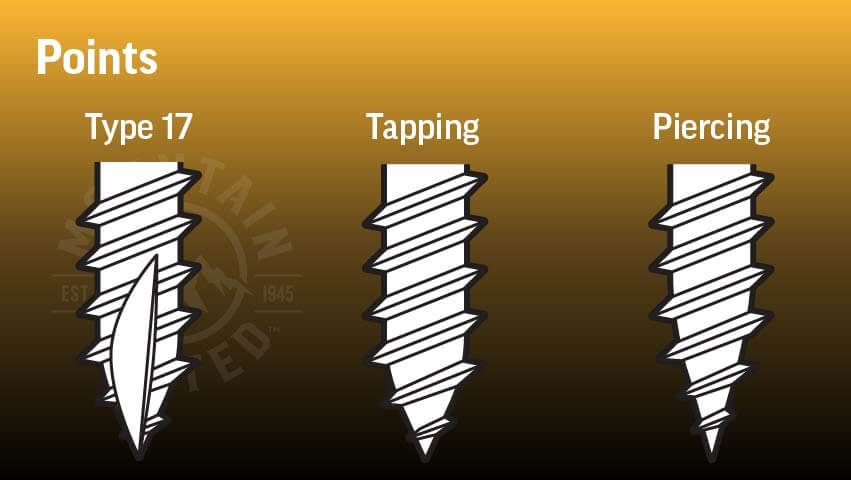

The tip is where the screw first engages with the material, and its design significantly impacts the ease and effectiveness of installation. Common tip types include:

- Type 17: Removes wood fibers during insertion, eliminating the need for pilot holes and reducing splitting.

- Self-Drilling: Functions like a drill bit, making it ideal for metal applications.

- Self-Piercing: Designed to penetrate thin materials like sheet metal without pre-drilling.

At Big Timber, the Type 17 tip is a hallmark of our screws, providing:

- Self-Drilling Action: Saves time and effort by eliminating the need for pilot holes in most wood applications.

- Splitting Prevention: Ensures clean and precise entry, protecting the integrity of the material.

Why Big Timber Fasteners Are Built to Perform

Every component of a Big Timber Fastener is designed with precision and performance in mind. Our screws deliver:

- Star Drives for superior torque and reduced cam-out.

- Aggressive threads for strong, durable connections.

- Type 17 tips for effortless, pilot-hole-free installation.

Unlike generic screws, Big Timber fasteners are crafted to perform under the toughest conditions. Whether you’re framing, decking, or tackling a complex DIY project, you can trust our products to get the job done right.

Take Your Projects to the Next Level

When each part of the screw works together seamlessly, the results speak for themselves. That’s why professionals and DIYers trust Big Timber Fasteners for strength, reliability, and ease of use.

Visit your local retailer today to experience the difference that Mountain Tested™ fasteners can make in your projects.