Fasteners are the backbone of any construction project, holding materials together and providing strength and stability. From screws to nails, bolts, and anchors, each fastener type has unique applications. Choosing the right fastener for your project ensures durability, safety, and success. Here’s a closer look at these essential components and how to select the best one for your needs.

Screws

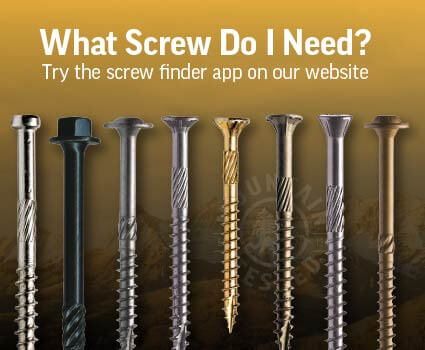

Screws are versatile fasteners that provide superior holding power and ease of removal, making them a preferred choice for many applications.

- Wood Screws:

Designed for wood-to-wood connections, these screws prevent splitting and ensure a strong, secure hold.- Examples: Big Timber’s BTX, WTX, YTX, and CTX screws are ideal for wood framing, trim, and general construction.

- Metal Screws:

Used for metal-to-metal or metal-to-wood connections. Self-tapping and self-drilling screws are commonly chosen for their ability to create threads without pre-drilling. - Drywall Screws:

These screws feature longer threads to provide a firm grip when attaching drywall to wood or metal studs. They install quickly and securely without damaging the drywall. - Masonry Anchors and Screws:

Designed for concrete, brick, and cinder block, these fasteners range from light-duty anchors to heavy-duty expansion anchors and masonry screws.

Tools: Use drills or impact drivers for proper screw installation, ensuring fasteners are driven securely. Beware, impact drivers, if used improperly, may over-torque or over drive screws.

Nails

Nails are traditional fasteners often chosen for their simplicity and speed of use.

- Common Nails:

Thicker nails designed for framing and structural work. While nails are fast to install, screws are increasingly preferred for their superior holding power and ease of removal. - Finishing Nails:

Lightweight nails with smaller heads, ideal for trim and finish work. However, trim or finish screws are often chosen instead for added strength and the ability to make adjustments if needed. - Roofing Nails:

Specifically designed for securing asphalt shingles. For metal roofing applications, screws with neoprene washers are preferred for durability and a watertight seal.

Tools: A hammer or nail gun is essential for installing nails quickly and securely.

Bolts

Bolts are heavy-duty fasteners designed for high-strength applications and are often used with nuts and washers.

- Hex Bolts:

Commonly used in woodworking, machinery assembly, and structural repairs. Hex lag bolts (lag screws) are used in applications where a nut isn’t required. - Carriage Bolts:

Ideal for wood-to-wood and wood-to-metal connections, these bolts offer exceptional gripping strength. In applications where nuts aren’t needed, lag bolts provide similar functionality.

Tools: Wrenches or socket drivers are necessary for tightening bolts to ensure a secure connection.

Anchors

Anchors are essential for securing fasteners into concrete, masonry, or other hard surfaces.

- Expansion Anchors:

Provide strong, reliable holds for structural elements in concrete. - Masonry Screws:

Used for attaching materials to concrete, brick, or stone. - Sleeve Anchors:

Versatile anchors often used for light to medium-duty applications, such as securing fixtures or railings. - Wedge Anchors:

Designed for heavy-duty structural work, these anchors provide exceptional stability for beams or machinery.

Tools: A hammer drill and the appropriate driver bit are crucial for proper anchor installation.

Choosing the Right Fastener for Your Project

- Match the Fastener to the Material:

Ensure the fastener is compatible with the materials being joined. For example, use ACQ-compatible fasteners for treated lumber to prevent corrosion. - Consider Load Requirements:

Select fasteners designed to handle the load and stress of your project. Screws, bolts, and anchors offer varying degrees of support for static and dynamic loads. - Use the Right Tools:

Choose tools like drills, impact drivers, hammers, or wrenches based on the fastener type to ensure proper installation. - Follow Building Code Guidelines:

Ensure your fastener choice complies with local codes and manufacturer recommendations for both fasteners and materials.

Build with Confidence

Understanding the unique benefits and applications of screws, nails, bolts, and anchors ensures your construction project is durable, safe, and successful. With fasteners designed for strength and reliability, Big Timber Fasteners provides the perfect solutions for any job.

Visit your local retailer or explore our Fastener Finder Tool at www.bigtimberfasteners.com to find the right fasteners for your next build.