Whether you’re tackling a DIY project or planning a large-scale construction job, selecting the right fastener is critical to the success of your build. The fastener you choose impacts the structural integrity, durability, and overall safety of your project. With so many options available, making the right choice can feel overwhelming.

By focusing on key considerations like material compatibility, load requirements, environmental conditions, aesthetics, and screw length, you can confidently choose the fastener that meets your needs.

Key Factors to Consider When Choosing Fasteners

-

Material Compatibility

Fasteners must be compatible with the materials they are joining to avoid long-term damage or failure.

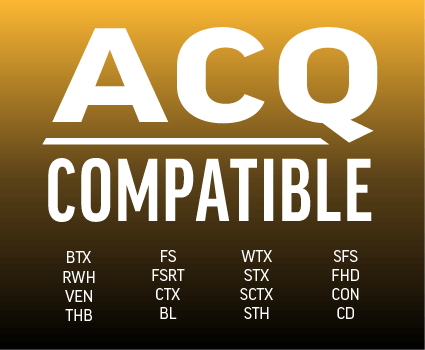

- Example: When working with ACQ-treated wood, it’s essential to use ACQ-compatible fasteners, as untreated screws can corrode when exposed to the chemicals in treated lumber.

- Tip: Consider the hardness and density of the materials. Hardwoods, softwoods, and engineered woods may require specific screw designs.

-

Load Requirements

Understanding the forces your fastener will encounter is crucial for maintaining structural integrity.

- Static (Dead) Loads: These are constant, non-moving forces, such as the weight of walls, floors, or permanent fixtures. Fasteners must be strong enough to support these loads over time.

- Dynamic (Live) Loads: These are temporary or moving forces, such as people, furniture, or vehicles. Ensure your fasteners can withstand vibrations and fluctuating pressures.

Tip: For heavy-duty applications, choose fasteners with high shear and withdrawal resistance, like Big Timber’s CTX Construction Lag Screws.

-

Assembly and Disassembly

Determine whether your project requires permanent connections or if it will need to be disassembled occasionally.

- Permanent Assemblies: Use fasteners like nails or screws that create a secure and lasting bond.

- Temporary Assemblies: Opt for screws, bolts, or other fasteners that can be easily removed without damaging the materials.

- Covered Screw Heads: If disassembly isn’t required, consider covering fastener heads for a polished, professional look using wood plugs or filler.

Screws, unlike some other types of fasteners, are versatile and can be used in permanent and temporary assemblies.

-

Aesthetic Considerations

In projects where fasteners are visible, their appearance can impact the overall design.

- Blending with Materials: Choose screws like the CD Screw, which are colored to match composite deck boards for a seamless, unobtrusive appearance.

- Standing Out for Visual Effect: Sometimes, you want your fasteners to be part of the design. For example, black screws can create a striking contrast on a pergola or decorative woodwork.

- Subtle Fasteners: Smaller screws, like those with a micro bugle head, are less noticeable, making them ideal for finishing or trim work.

-

Environmental Conditions

Environmental factors like moisture, temperature extremes, and chemical exposure can affect the performance of your fasteners.

- Moisture and Corrosion: For outdoor environments, choose fasteners with corrosion-resistant coatings, like BTX Screws, or materials like 316 Marine Grade Stainless Steel, which offer exceptional resistance to rust.

- Temperature Extremes: Ensure fasteners can withstand expansion and contraction due to heat and cold, particularly in metal or composite materials.

- Chemical Exposure: Use stainless steel fasteners for environments exposed to salt, chlorine, or industrial chemicals, ensuring durability and longevity.

-

Choosing the Right Screw Length

The length of the screw is just as important as its type and material.

- General Rule: A screw should penetrate at least 1.5 times the thickness of the material it’s securing into the base material. For example, if attaching a 1-inch board to a 2-inch beam, the screw should be at least 2.5 inches long.

- Avoid Over-Driving: Ensure the screw isn’t so long that it protrudes through the other side, causing safety or aesthetic issues.

- Big Timber Tip: Our screws come in a variety of lengths to suit all your construction needs, from trim and siding to framing and decking.

Types of Fasteners for Common Applications

- Framing and Structural Work: Use BTX Screws for wood framing or CTX Screws for log construction, timber frames, or SIP panels.

- Decks and Outdoor Structures: Opt for BTX Screws for general outdoor use, SWD Screws for softwood decks or CD Screws for composite decking.

- Roofing: Choose WB or EWB Screws for metal roofing and post-frame construction.

- Drywall: Use DWC or DWF Drywall Screws for securing drywall to wood or metal studs.

- Cabinetry and Trim: Select RWH Screws for cabinet installation and THB or FS Screws for trim and siding.

Building with Confidence

Selecting the right fastener for your project doesn’t have to be complicated. By considering material compatibility, load requirements, environmental factors, aesthetic needs, and proper screw length, you can ensure your project’s success.

At Big Timber Fasteners, we provide high-quality, Mountain Tested™ fasteners designed for strength, durability, and ease of use. Explore our range of fasteners and resources, like the Big Timber Fastener Finder Tool, to make confident choices for your next construction project.

Visit your local retailer or go to www.bigtimberfasteners.com to get started today!