Fasteners are essential in any construction project, playing a critical role in maintaining the durability, longevity, and safety of a building. They secure connections, distribute loads, and provide resistance against various forces, ensuring the structural integrity of the entire framework.

At Big Timber Fasteners, we engineer our products to meet the demands of modern construction, offering strength, reliability, and safety. Let’s explore the vital roles fasteners play in construction and why quality matters.

1. Load Distribution

Fasteners help evenly distribute loads across structural components, preventing excessive stress on any single area. This is especially important in wood construction, where fasteners join wood-to-wood or wood-to-other materials.

Key Considerations for Load Distribution

- Type of material (e.g., hardwood, treated lumber).

- Environmental conditions (e.g., moisture, temperature extremes).

- Specific project requirements (e.g., load-bearing capacity).

Tips for Ensuring Clamp Load

2. Connection Stability

Fasteners secure building components, such as beams, joists, and panels, ensuring they remain in place under load and stress.

Structural fasteners are specifically designed for high-stress applications, where connections must support significant weight and resist wear over time.

Big Timber’s Structural Fasteners

Big Timber’s fasteners are engineered and tested for superior performance, with detailed structural properties outlined in our Technical Evaluation Reports (TERs). These fasteners provide the strength and reliability needed for critical building components.

3. Resistance to Forces

Buildings are subject to various forces, including wind, seismic activity, and the weight of the structure itself. Fasteners must resist these forces to maintain stability.

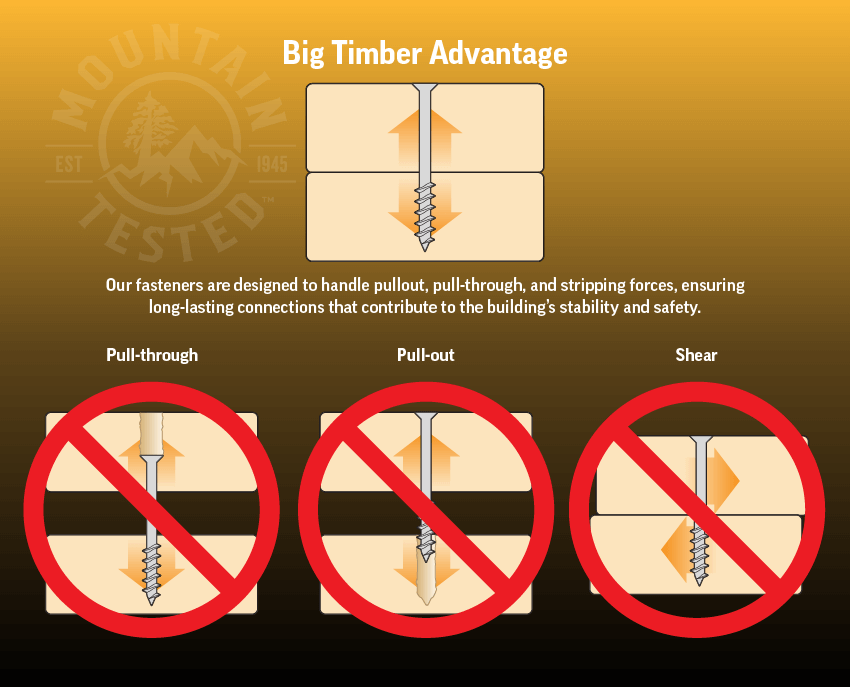

Our fasteners are designed to handle pullout, pull-through, and stripping forces, ensuring long-lasting connections that contribute to the building’s stability and safety.

4. Durability

The durability of fasteners directly impacts the longevity and safety of a structure. High-quality fasteners can withstand environmental challenges and resist wear over time.

Why Quality Matters

5. Safety

Fasteners are a critical safety component in construction. Properly installed, high-quality fasteners reduce the risk of structural failures, protecting both occupants and the construction team.

• Big Timber Commitment:

Our fasteners undergo rigorous testing to ensure they meet the highest safety standards, giving you peace of mind on every project.

The Anatomy of a Big Timber Screw

Big Timber screws are designed to provide superior performance and reliability. Key features include:

Why Choose Big Timber Fasteners?

When it comes to structural integrity, using premium fasteners is essential. Big Timber fasteners are:

Building Strong, Safe Structures with Big Timber

Fasteners are more than just connectors—they’re the foundation of structural integrity in every building. By choosing high-quality, tested fasteners like those from Big Timber, you can ensure your project’s safety, durability, and performance for years to come.

Explore our range of Mountain Tested™ fasteners at www.bigtimberfasteners.com or visit your local retailer today to learn more about how we can support your next construction project.